Automatic hole expansion testing at Salzgitter Flachstahl

11.03.2020 | Salzgitter Flachstahl GmbH

The requirements expected of components in the automotive industry are constantly increasing. Salzgitter Flachstahl began to address these demands some years ago and has established the hole expanding test as a standard production-parallel procedure. The most widespread method of measuring hole expansion is as described in ISO 16630. This involves expanding a hole with a conical punch until cracking occurs. The hole expansion ratio (HER) is defined as the ratio of the change in diameter relative to that of the initial hole. In other words, with a hole expansion ratio of 60%, the hole has become 60% larger before a crack occurs. The latest version of the ISO standard contains a new definition of the cracking criterion. Previously, the expansion test was stopped as soon as a crack penetrated through the full thickness of the steel sheet. Now in addition the crack must reach a width of 0.1 mm, at which point the test should be halted. This can no longer be guaranteed by manually aborting the test.

Besides the new ISO, customer requirements in respect of the guaranteed HER for deliveries of steel from Salzgitter Flachstahl have also become more stringent, with the result that manual capacities for ensuring prompt production-parallel testing were approaching their limits.

With this in mind, Salzgitter Flachstahl took the decision to install an automatic hole expanding system.

This is comprised of two separate units, the blanking press and the hole expander itself.

All of the holes required for subsequent expanding are stamped out simultaneously in the blanking press. The cutting process is automatically controlled and monitored.

The holes in the sheet are then individually expanded in the hole expander until cracking occurs, and evaluated. The sheets are automatically transferred to the expanding press from a magazine and arranged in place. While this is happening, a plausibility check is carried out in order to eject unknown or implausible sheets.

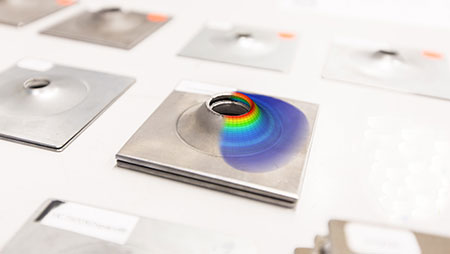

The test is carried out with the aid of an image capture system which automatically detects cracking. The requisite software was programmed in cooperation with research company Salzgitter Mannesmann Forschung GmbH. This enables measurements to be made independently of any manual operator, thereby reducing the potential for error.

The hole expanding system was inaugurated at a customer event in November 2019, when selected customers had the opportunity to satisfy themselves of Salzgitter Flachstahl’s powers of innovation and assess the new system in detail.